Last Updated on March 6, 2020

There are many different types of materials used in motorcycle helmets and we’d like to share why these different materials are used to protect your head.

There are some materials that are used more than others and there are some materials that are only used with the most expensive helmets.

It’s true that the more you pay, the higher quality and more durable material you’re going to get out of a helmet but some of the materials used in the more affordable protective helmets do just fine.

With that, let’s go ahead and look into the different types of materials used in motorcycle helmets.

Motorcycle Helmet Materials

The materials used in a motorcycle helmet is important because it can tell you whether or not it’s a material that is suitable to absorb impact and resist abrasions.

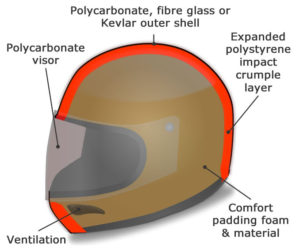

Every helmet is made in layers. The outer shell layer protects from the initial impact in a wreck and the inner cushion liner provides extra comfort and is also protected by the outer shell.

The outer shell is where the materials used is most important because if the outer shell isn’t made of something tough enough to withstand heavy impact then the inner liner can be punctured through and deal damage to the head.

A helmet is just like a skull.

A bigger skull.

A skull for the skull, if you will.

A skull protects the brain. Skull fractures aren’t the main worry when it comes to a motorcycle crash, brain injury is the real danger that is involved.

Just like how if your helmet and gear gets damaged in an accident, you aren’t too worried about the gear anymore because it did its job.

Skull fractures usually aren’t life threatening unless the fracture is to an extreme level. However, brain damage can more easily lead to indefinite disabilities and death compared to skull fractures.

Brain tissue is very hard to fix. Bones are much easier to fix and they usually are able to heal themselves relatively quickly.

This is how and why helmets were designed the way they are – they’re supposed to be able to twist or pull out of shape during a wreck so that it can further protect the skull which is the main protector of the brain.

So if the helmet is made of materials that are proven to protect the skull at an optimal level then it’s good to go!

Outer Shell

Let’s first dive into the materials used in the outer shell of a helmet.

The main material used will depend on how much the helmet costs.

Helmet manufacturers also focus on comfort, usability and extra features when they have the helmet cost in mind but the more you pay then the fancier materials you’re going to get out of the helmet.

Lighter materials that provide great protection are high in cost of labor.

That’s why the lower priced helmets are a lot heavier in comparison – they’re made of heavy plastics and the more expensive helmets are made of composite materials such as fiberglass fortified with carbon fiber.

Thermoplastics

Thermoplastics such as polycarbonate are the most used material because it’s cheaper to make, extremely tough and proven to hold out against impact.

Because of how polycarbonates are made, this results in heavier helmets.

Other polycarbonate applications include bullet resistant windows, some riot shields and for a Lockheed Martin F-22 cockpit canopy.

It’s used in a wide variety of products that need plastics that are high in durability and it’s no different for motorcycle helmets. Polycarbonate is tough enough for the roads.

The Icon Alliance Dark helmet is a great example of a polycarbonate helmet done right.

Fiberglass

As for other materials used, the main materials in the more expensive helmets includes fiberglass. More specifically, fiberglass that’s usually fortified with carbon fiber or kevlar.

It’s a material made of a polymer matrix and fibers combined. The fiber materials increase the overall strength of the polymer which is how materials such as carbon fiber and kevlar are made.

Carbon Fiber

Carbon fiber reinforced polymer is the most used material for the higher priced helmets.

The process of creating a helmet made out of carbon fiber is a lot harder to do comparatively to polycarbonate helmets. That’s why they’re more expensive.

As a result of creating a carbon fiber helmet you get a helmet that is 5x stronger than steel and twice as rigid but it’s also much lighter than steel.

That’s why carbon fiber helmets are so popular. They give extreme protection in a helmet that optimizes comfort and mobility.

Kevlar

You don’t see too many helmets on the market that are termed or labelled as a kevlar helmet.

This is because most of the higher priced helmets use carbon fiber and kevlar combined and the market is mainly looking for carbon fiber helmets.

LS2, AGV and Bell are a few notable brands that use kevlar within the carbon fiber in some of their helmets. It’s not entirely necessary to use kevlar in a helmet but when kevlar is used it strengthens the helmet even further.

Kevlar is a powerful synthetic fiber that is commonly used in military helmets/vests, sometimes cycle tires and other pieces of motorcycle gear.

Inner Layers

There is a stocky and solid inner layer that is between the comfort liners and the outer shell of the helmet.

This layer is responsible for being a cushion upon impact to prevent your head from being injured. It absorbs the shock and supplants the energy. This is called EPS or “Expanded Polystyrene foam”.

This is not to be mistaken for the inner comfort layer of a helmet.

Comfort layers are usually made of nylon and/or a type of comfortable padding to simply provide comfort while wearing the helmet while also wicking moisture away.

Be Wary of Low Quality Helmets

If you’re spending under $100 on a helmet then you need to heavily research the helmet before you move on to purchasing it.

There are helmets on the market that state they are “DOT approved” but when put to the test they are very easily destroyed.

When it comes to any piece of gear, the helmet especially, you simply cannot cheap out on them too much. While it makes complete sense to be on the lookout for affordable helmets on the market… You’ve got to make sure that it can protect you!

Check out the following video from FortNine, they perfectly demonstrated what it’s like to own one of those super cheap helmets.

It’s incredible seeing that some of these off-brand “knock off” companies are able to get away with advertising that their helmets have the viable protection that you need.

Makes me feel bad for those that haven’t done the research to know which materials and tests need to be done in order to prove that a helmet is viable…

These Materials Protect Your Head

Polycarbonate, carbon fiber composites and EPS.

When combined together in the right way and put through the strenuous tests to be DOT or even Snell approved… That’s when you’ve got yourself a good helmet.

Don’t fall for the cheap brand marketing tactics of them simply stating that their gear is made out of this or that… You have to dive deep into the research to ensure your helmet is going to protect you.

If you find it hard to research a specific company’s helmet and the tests done/materials used then you should simply move onto a different helmet.

A good helmet manufacturer makes sure that their customer understands that the helmet was designed with optimal safety in mind.

Which helmets have you been looking into getting?

Do you have a better understanding of motorcycle helmet materials after reading through our post?

Let us know in the comments below!

What’s up! I’m Colton, the main guy behind Moto Gear Knowledge. Gear has always been my #1 priority when it comes to riding.

I share my experiences regarding gear and anything else moto related with you here. 👍